Navigating ESG Risks and Opportunities in the Manufacturing Supply Chain

According to the World Economic Forum, by 2030, water demand is expected to outstrip supply by 40%, and extreme weather events are projected to cost businesses $1.3 trillion annually.

Resource scarcity and climate change are among the most pressing environmental risks facing the manufacturing supply chain.

How will these risks affect supply chains?

As global populations grow and industrialization intensifies, the demand for natural resources is outpacing supply, a situation worsened by climate change disrupting ecosystems and reducing resource availability. This leads to increased costs and supply chain disruptions.

Climate change impacts physical infrastructure through extreme weather events, causing producing and transportation delays, increased costs and revenue loss.

Regulatory responses to climate change, such as carbon pricing and emissions reduction mandates, further impose financial burdens on manufacturers.

The Time to Act on Sustainability is Now

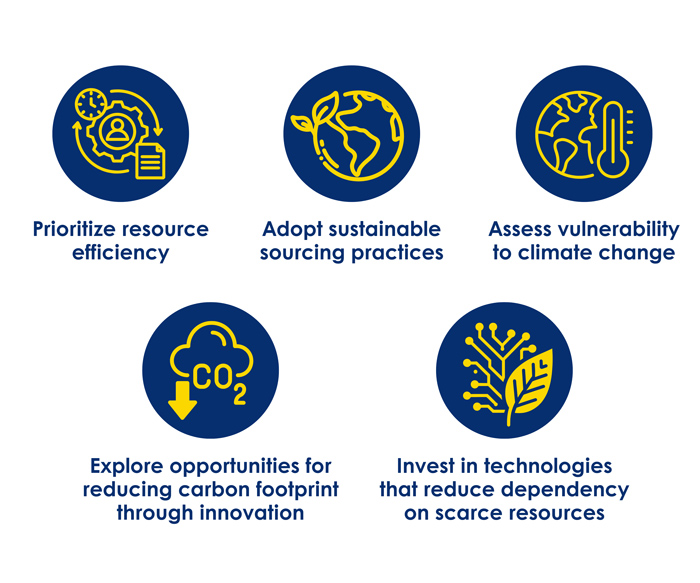

To mitigate these risks, companies need to adopt proactive strategies and take urgent action to:

By embedding Environmental, Social and Governance (ESG) principles into every facet of the supply chain, your company can create a future that is not only sustainable but also profitable and resilient in the face of change.

Harnessing Innovation for Sustainability

How can implementing innovative sustainability initiatives benefit your organization?

Not only do these initiatives reduce environmental impact, but they also generate substantial cost savings through improved efficiency, waste reduction and resource optimization. Through the power of innovation, they can create new revenue streams and improve brand value, helping your company stay ahead of market trends and meet growing consumer demand for sustainable products.

Success Stories of Innovative Environmental Initiatives

Companies can achieve significant cost reductions through efficiency improvements, such as sustainable sourcing, the adoption of green technologies, circular economy initiatives and waste reduction strategies.

- Example: Through its Project Gigaton initiative, Walmart and its suppliers have avoided over 230 million metric tons of emissions as of 2020, while the company’s energy efficiency programs have saved more than $1 billion in energy costs since 2010.

ESG initiatives can also be a catalyst for innovation and new product development, including packaging innovations, product reformulations and digital solutions.

- Example: Loop by TerraCycle has partnered with major consumer packaged goods brands to create a circular shopping platform. Consumers can purchase products in durable, reusable packing that is returned, cleaned and refilled. This innovation has created a new market for zero-waste shopping.

These examples demonstrate that implementing sustainability initiatives in supply chains can lead to substantial cost savings, drive innovation, create new market opportunities and address environmental challenges.

Common Pitfalls in ESG Integration

The successful integration of environmental principles goes beyond mere compliance. It involves embedding them into the core of your supply chain strategy.

By aligning environmental goals with overall business objectives, your company can create a cohesive strategy that drives sustainable growth and competitive advantage.

But beware! Companies often encounter common pitfalls that can undermine their sustainability goals and long-term success. These missteps include an overemphasis on short-term gains over long-term sustainability, inadequate investment in environmental initiatives, greenwashing and its consequences and a lack of integration with core business strategy.

Your Roadmap to a Greener Future

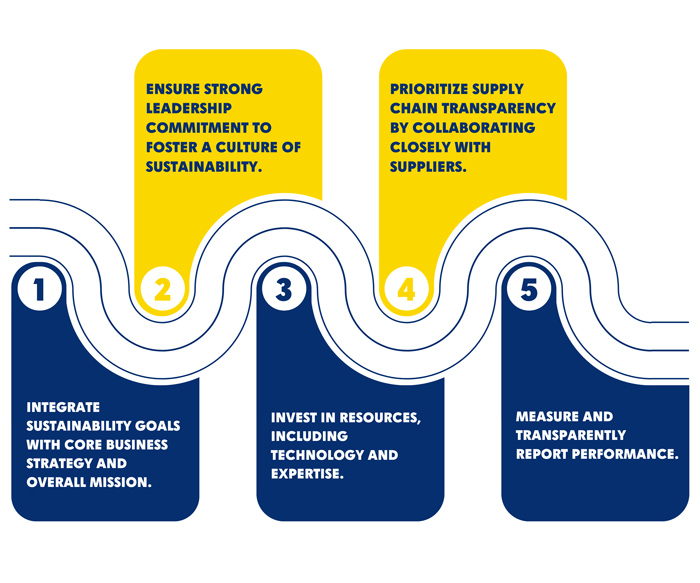

To avoid these pitfalls and successfully implement environmental strategies, companies need a multifaceted roadmap that addresses both strategic and operational challenges:

As we move into 2025 and beyond, the ability to set and achieve meaningful ESG targets will be a distinguishing factor for industry leaders. Our Corbus team can support your organization in creating a proactive and strategic roadmap for ESG integration within your manufacturing supply chain.

For those who seize the opportunity, the rewards will be significant—from enhanced corporate reputation to a stronger, more adaptive supply chain capable of thriving in the next era of manufacturing.